Our Approach to Design

Advanced Engineering + Product Development

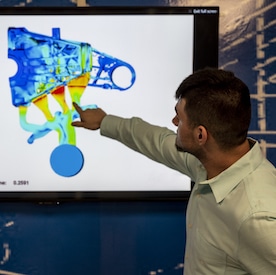

Gibbs advanced engineering works collaboratively with customers to hone designs for cost-effective manufacturing. This relationship begins with initial design and follows through to production and beyond.

Beginning with a blank-sheet concept to gather inputs and requirements, we want to fully understand our customer’s goals. Then we use state-of-the-art tools such as FEA, and flow simulation to identify and address critical factors and variables which result in long-term success.

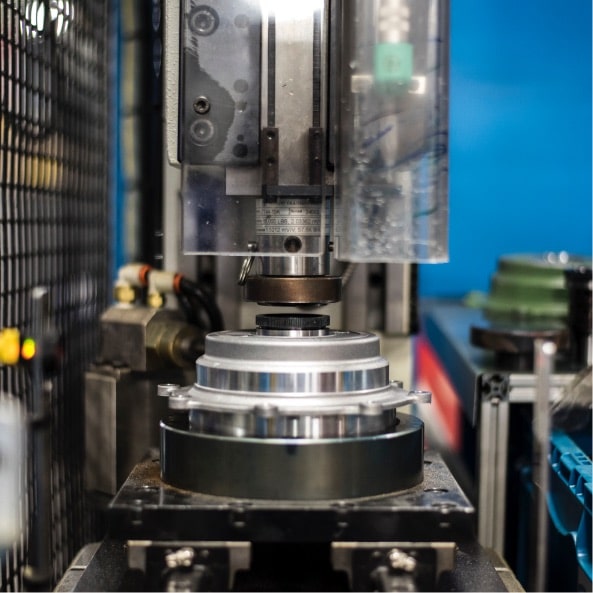

Additionally, multiple prototyping options support our product development process. Gibbs can provide rapid prototypes, sand castings, and production intent HPDC components – all with engineering support to monitor results and recommend necessary changes.

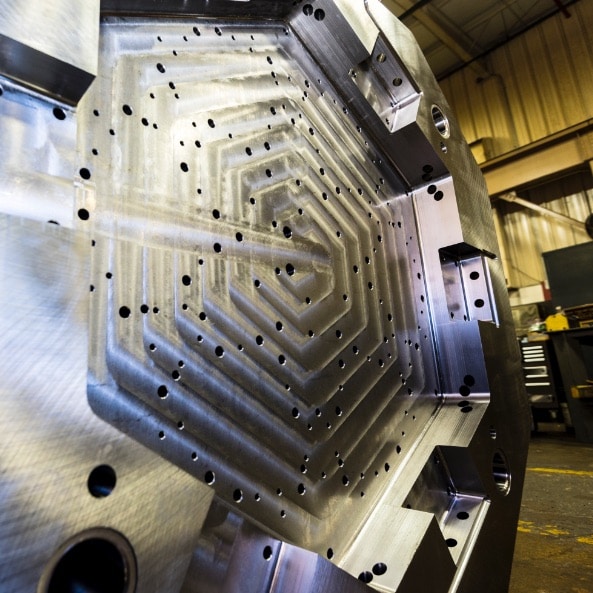

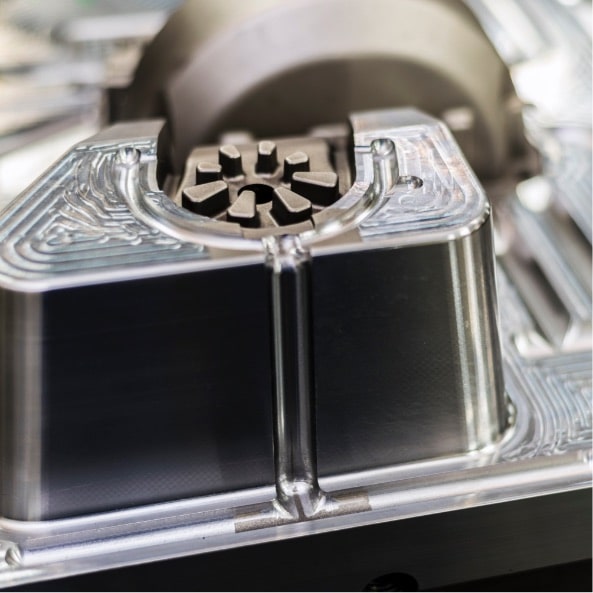

Process Development + Design

Gibbs develops casting processes using all pertinent industry standards. Mold flow, solidification, and thermal distortion tools are used to simulate the casting process to permit optimal tool configuration and process set-up conditions prior to all tool builds.

Gibbs has in-house capabilities for manufacturing cell design. Using virtual reality tools, we optimize our processes and translate your visions into workable designs.