Capabilities

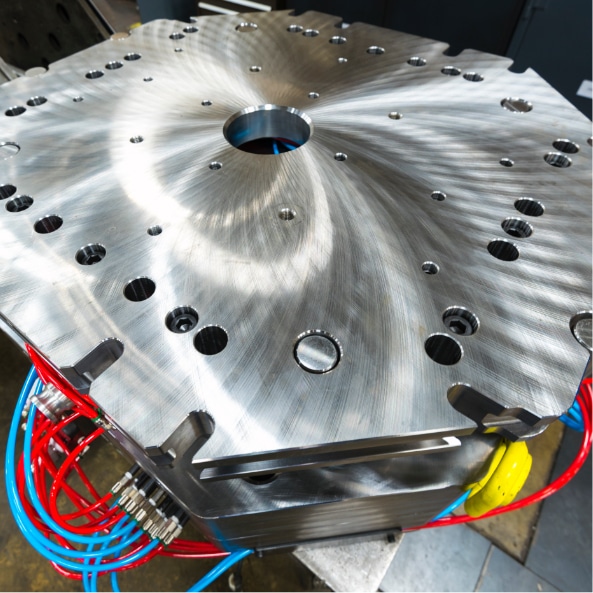

60 years of leadership in die casting, machining, and assembly makes Gibbs a leading supplier for its Tier One and OEM customers. With four distinct capability areas, we deliver high volume, precision parts at competitive prices. To learn more, explore our extensive product gallery.